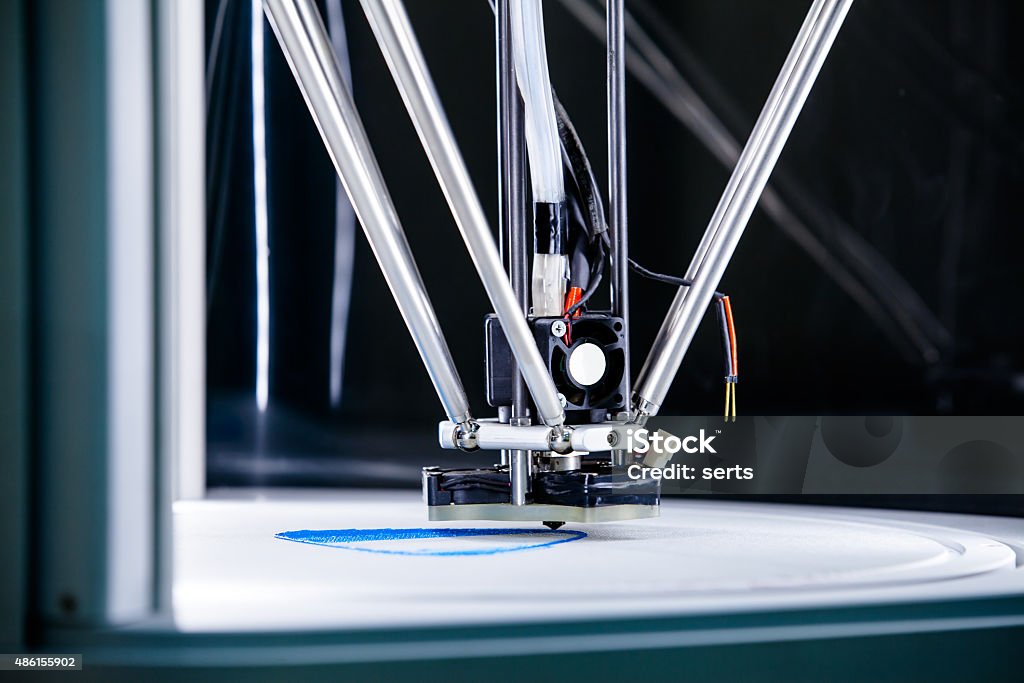

The world of 3D printing has opened doors to innovation across many industries, and one of the most exciting applications lies in toy design. If you’ve ever wanted to bring a character or concept to life, the ability to 3D print custom toy models is now within reach for designers, hobbyists, and brands alike.

Why 3D Printing is Ideal for Toy Production

3D printing provides unmatched flexibility and speed, especially for prototyping and small-batch production. Whether you’re designing a collectible, a character for storytelling, or a unique product for merchandising, 3D printing offers precision and efficiency that traditional manufacturing lacks.

Advantages of Using 3D Printing for Custom Toys:

- Rapid Prototyping – Quickly test and refine designs before final production

- High Detail Resolution – Capture small features and textures for realistic finishes

- Low Volume Friendly – Ideal for limited-edition runs or samples

- Material Versatility – Choose from resins, PLA, ABS, or vinyl depending on the toy’s purpose

The Custom Toy Printing Workflow

Here’s what the typical process looks like when you want to 3D print custom toy designs:

| Step | Description |

| Digital Design | Begin with a 3D model (.STL, .OBJ), either created from scratch or scanned |

| Slicing & Setup | Prepare the file for the printer with correct orientation and supports |

| Printing | Use SLA or FDM printers depending on the desired finish and size |

| Post-Processing | Clean, cure, sand, and paint for a finished look |

| Optional Casting | For mass production, use the print to create a master mould |

Who’s Printing Custom Toys?

This approach benefits a variety of groups:

- Toy Designers – Wanting to showcase concepts or test prototypes

- Artists and Illustrators – Translating 2D concepts into physical art

- Startups and Brands – Launching character-driven merchandise

- Collectors – Creating exclusive, small-batch items

Useful Tips:

- Keep your design compact for faster print times.

- Avoid overly thin structures; they may break during support removal.

- Choose SLA printing for ultra-smooth detail and better painting surfaces.

Conclusion

The ability to 3D print custom toy figures is no longer limited to large companies. With access to skilled service providers and affordable technology, almost anyone can bring their idea to life — quickly and affordably.To begin your own toy design journey, visit R3DPrints’ Designer Vinyl Toy Production.