What are Threaded Fittings?

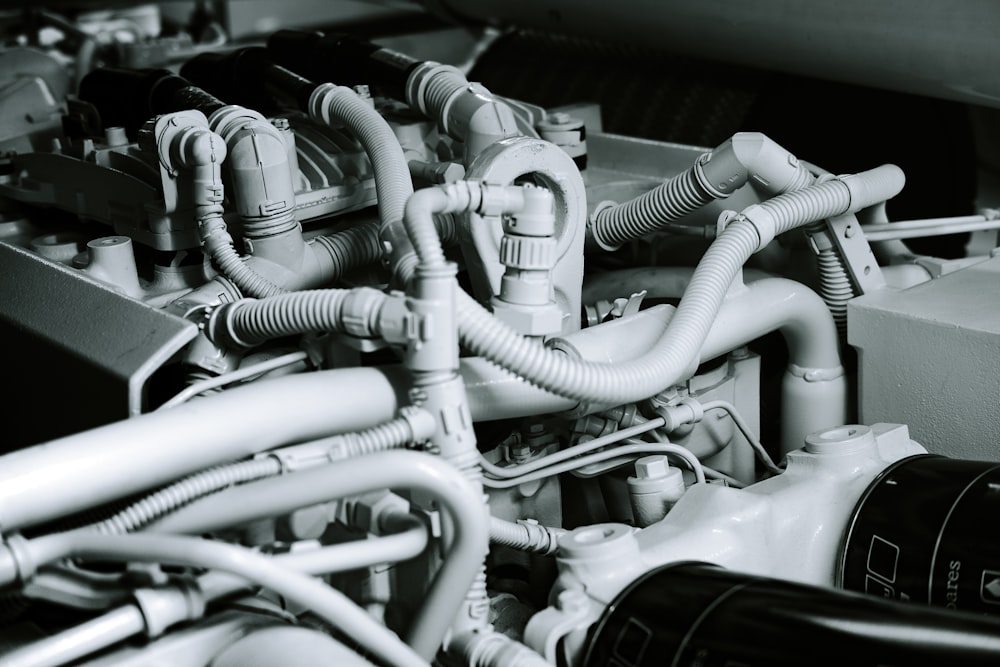

Threaded joints probably represent one of the oldest methods of joining piping systems. Like Socket Weld fittings, threaded fittings are mainly used for small pipe diameters; generally for piping with a nominal diameter that is NPS 2 or smaller. Threaded piping is usually used in low-cost, noncritical applications such as domestic water, fire protection, and industrial cooling water systems. Cast gray or malleable iron, cast brass or bronze, or forged alloy and carbon steel is used used to make threaded fittings. Threaded fittings are available in three pressure ratings which are, Class 2000, 3000, and 6000.

What is the Purpose of Threaded Fittings?

The threaded pipe provides gas or liquid-tight connections that are mechanically strong. Pipe threads have many national and international standards. They vary according to the intended usage, such as garden hose threads and fire hose threads among others. So, try threaded fittings malaysia.

What are the Advantages?

Firstly, threaded fittings have high joint strength, according to the principle of cold work hardening steel on steel rolling straight thread strength greatly increased, so that the straight thread connection of tensile strength is higher than the tensile strength of steel. Next, threaded fittings provide stable and consistent performance, and therefore the connection process is not affected by the quality of the worker. Moving on, threaded fittings can be connected swiftly, because use of over-the-counter precast, field assembly connection manner, so steel prepared wirehead can be prefabricated reinforced yards of reserves. The time limit is tight, just in the construction site, the assembly workers can work quickly. Fourth, threaded fittings are available to be used in a wide range of applications, and basically do not have any restrictions on the application be used, be it for the bending steel, fixed steel bar, steel reinforcement cage, and other steel that can’t rotate. Fifth, threaded fittings are easy to manage, won’t appear in the sleeve and if the phenomenon of the steel bar does not match, the test is more convenient. After several hours of simple operation, by ordinary workers, it can become a way for them to learn to become skilled workers. Sixth, there is the economic benefit and social benefit in the usage of threaded fittings. This is because the construction period is shortened, the engineering quality is improved and the energy consumption is reduced, which contributes to environmental protection, and reduced equipment investment. Last but not least, the usage of threaded fittings leads to a reduction in labor intensity, since it only requires a silk head that carries out a one-step process, in a dedicated thread rolling machine.